HUBS_

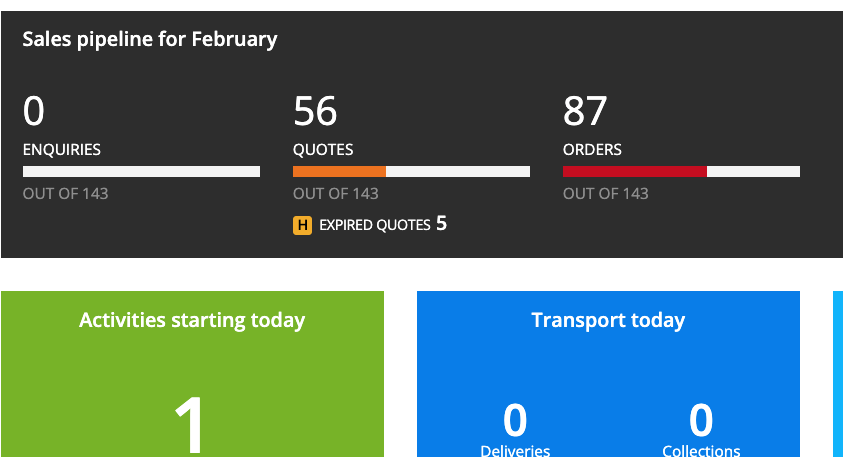

A growing collection of focused tools designed to extend and enhance Current RMS, each Hub solving a specific real world problem across warehouse, prep, transport, admin, and operations.

Every Hub is built from day to day use in live rental environments. Some automate repetitive tasks, others surface critical information faster, and many quietly remove the friction that slows teams down.

Below is a full overview of the Hubs currently available, and what each one does.

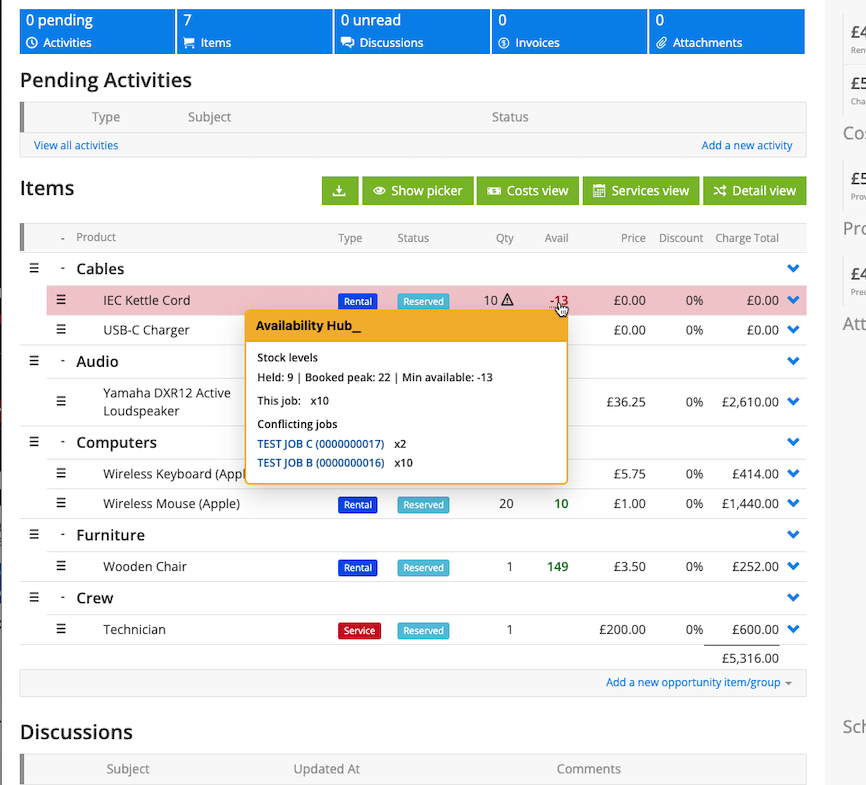

Availability Hub_

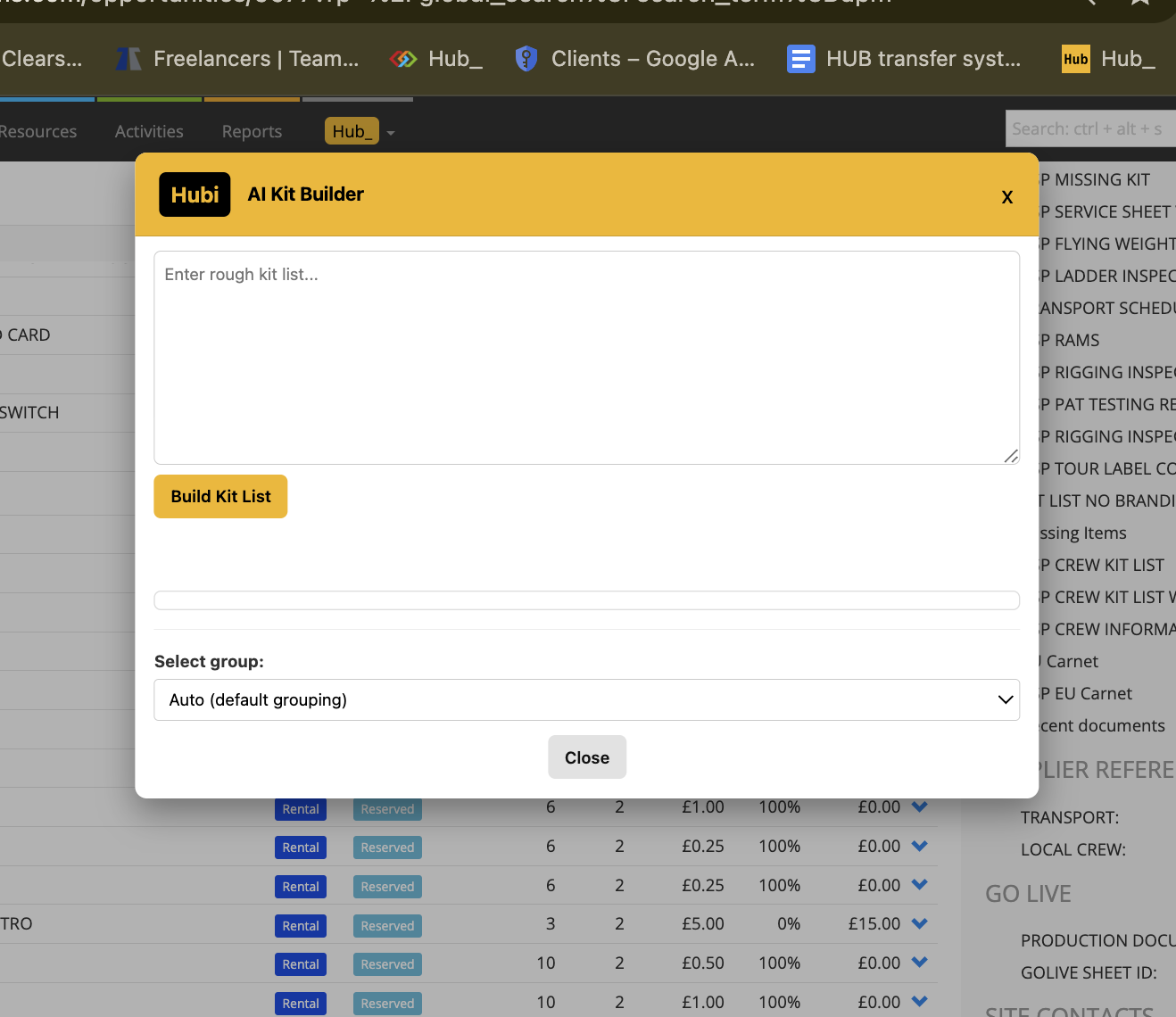

Hubi

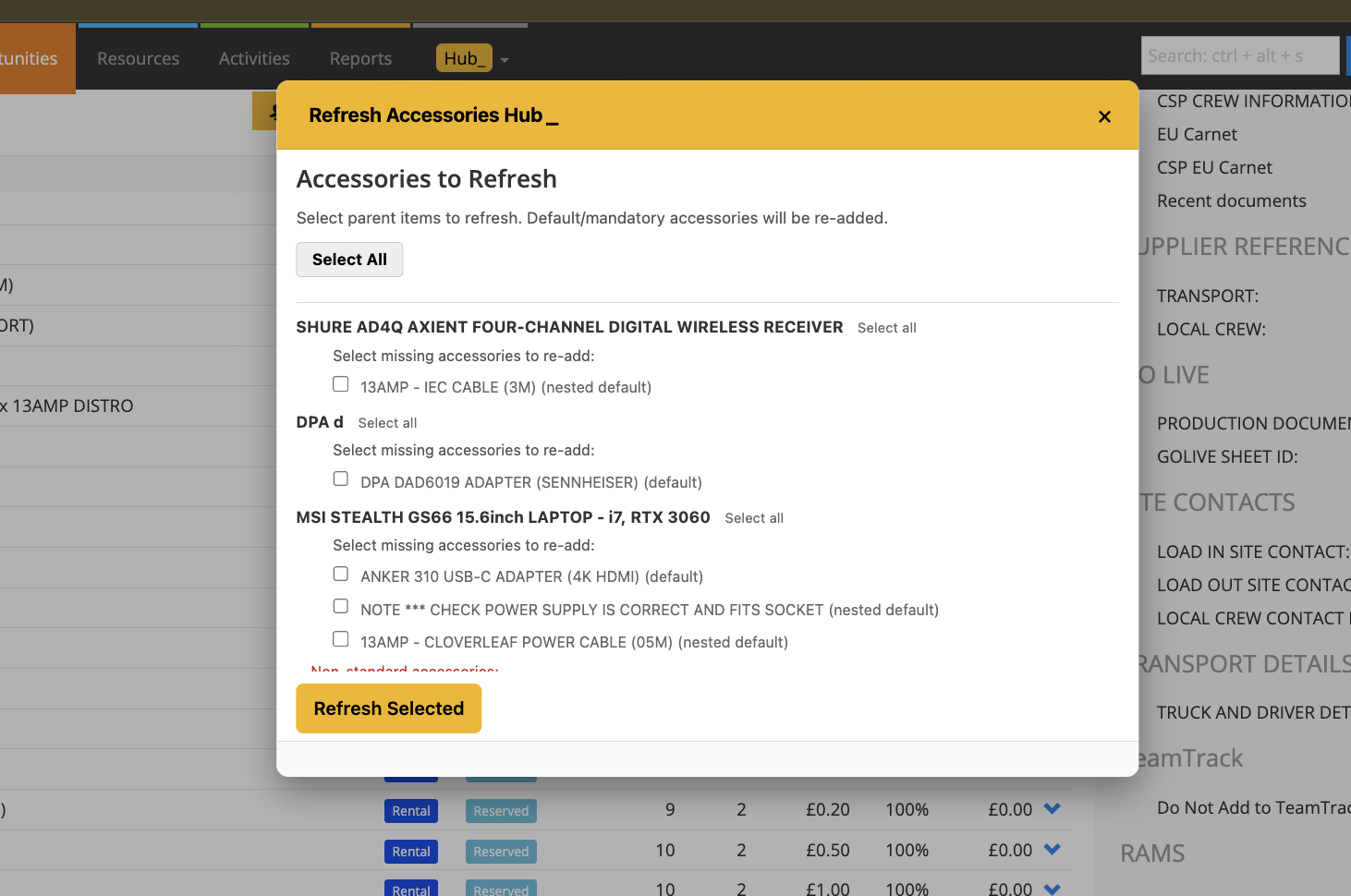

Refresh Accessories Hub_

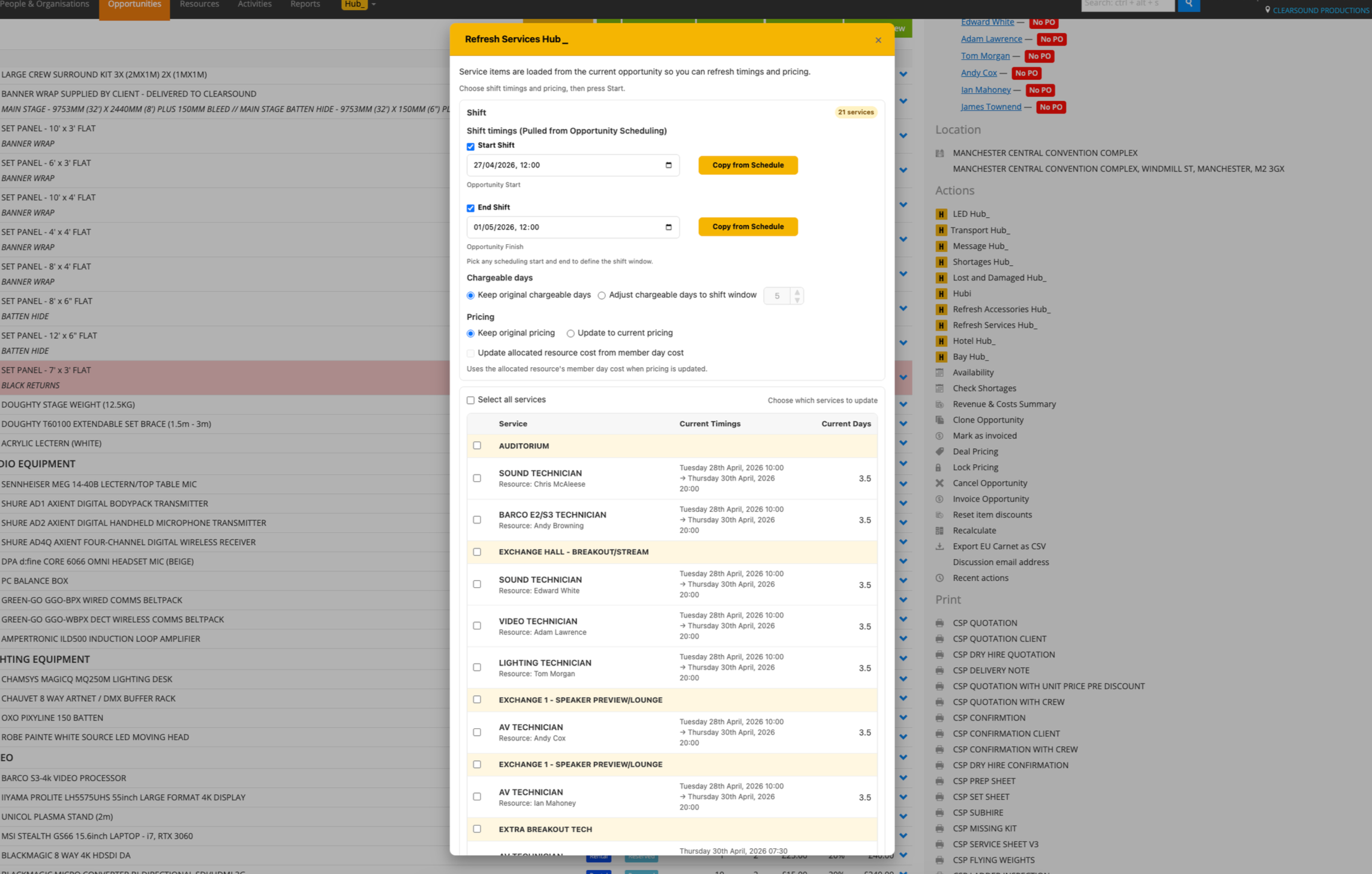

Refresh Services Hub_

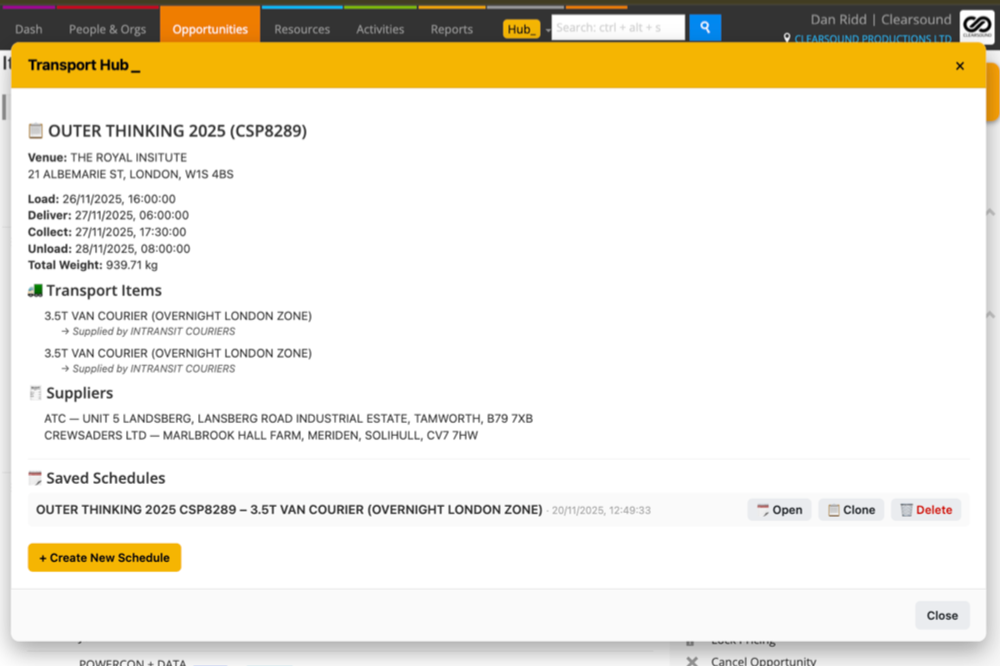

Transport Hub_

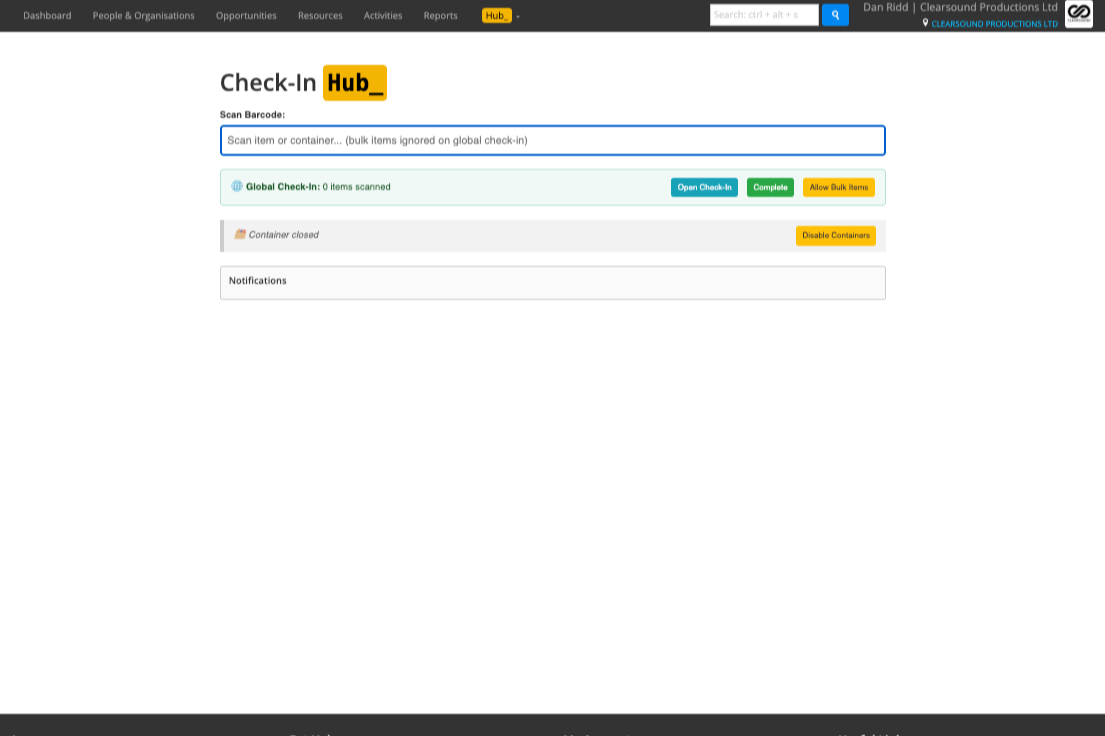

Check-In Hub_

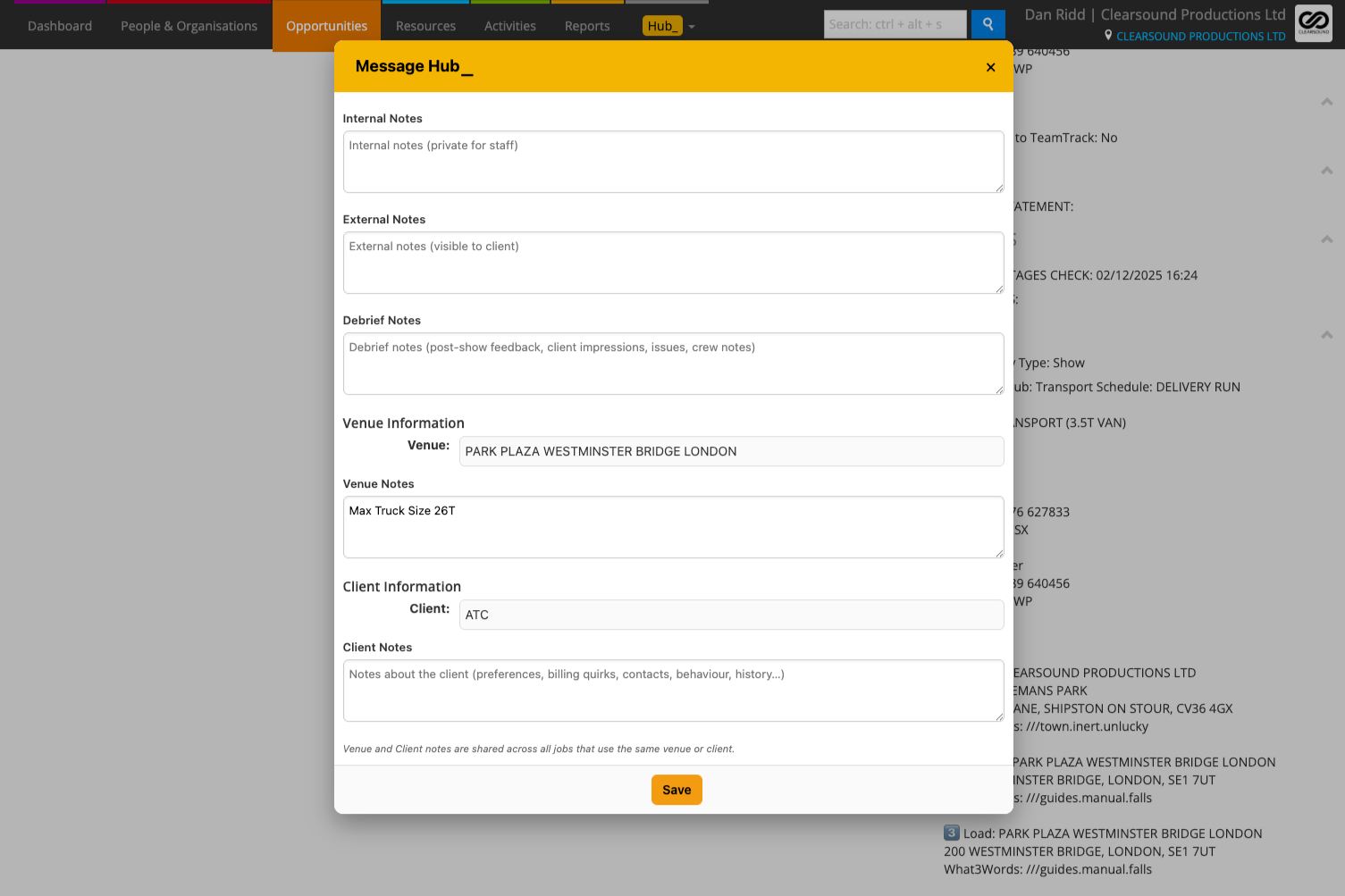

Message Hub_

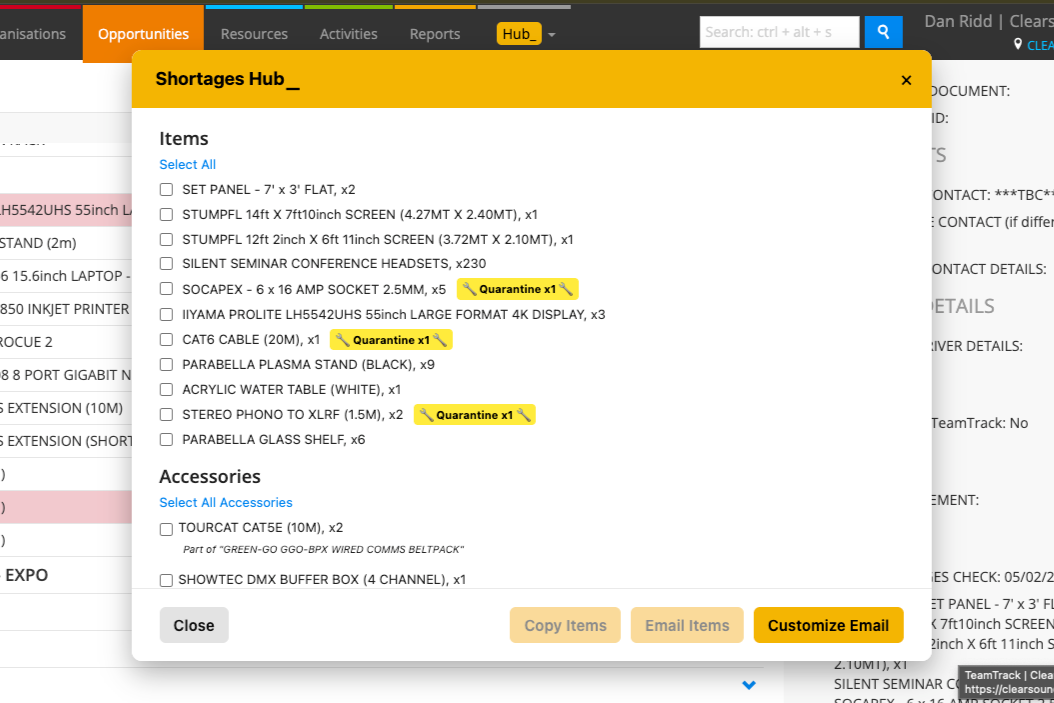

Shortages Hub_

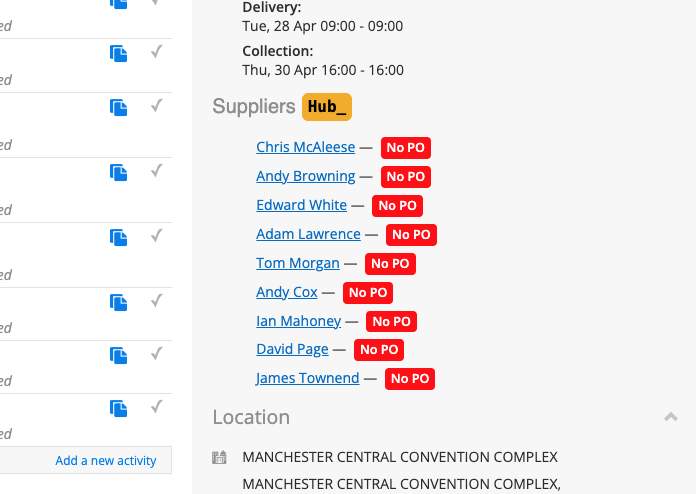

Suppliers Hub_

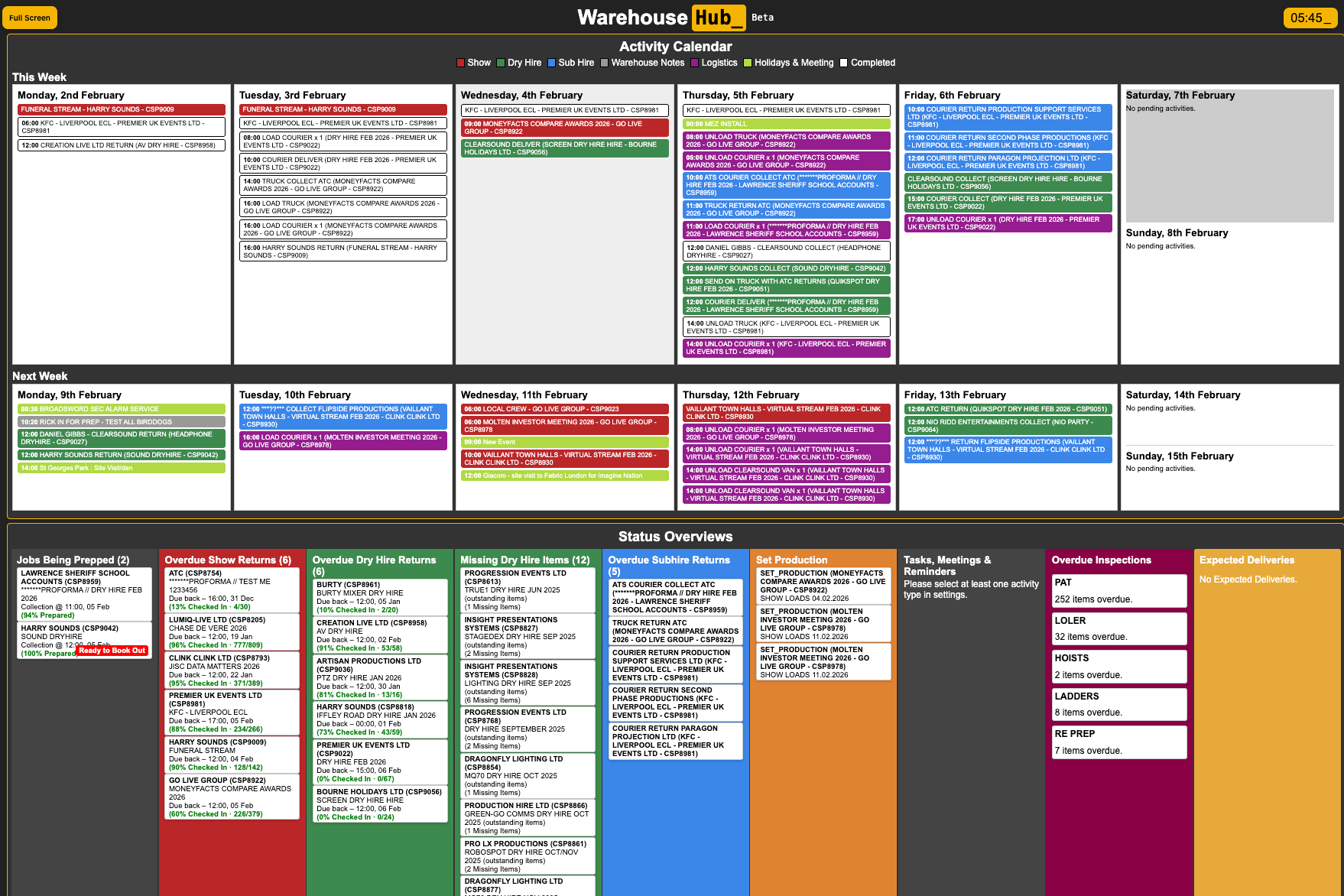

Warehouse Hub_

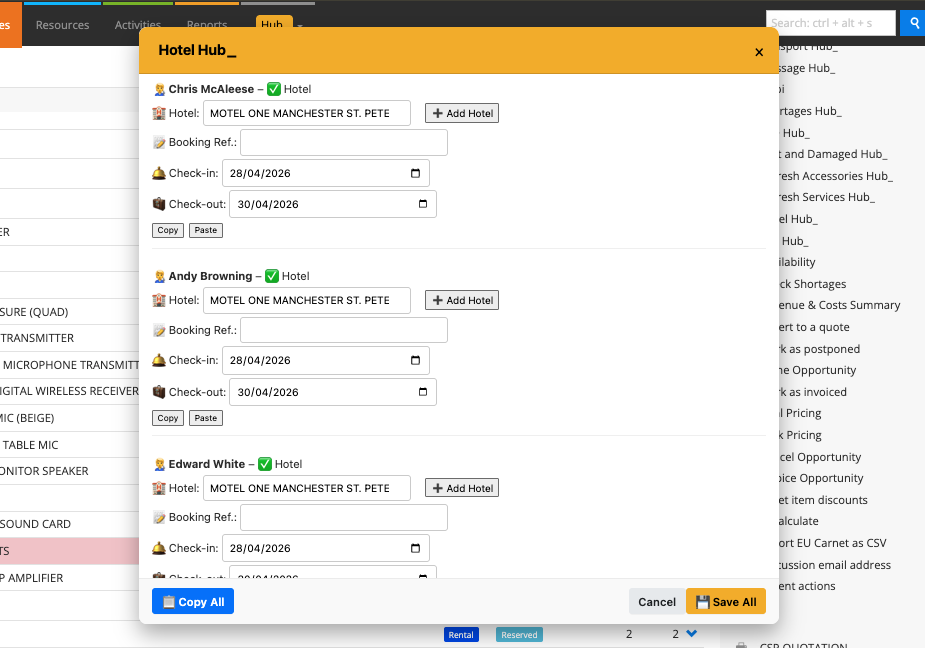

Hotel Hub_

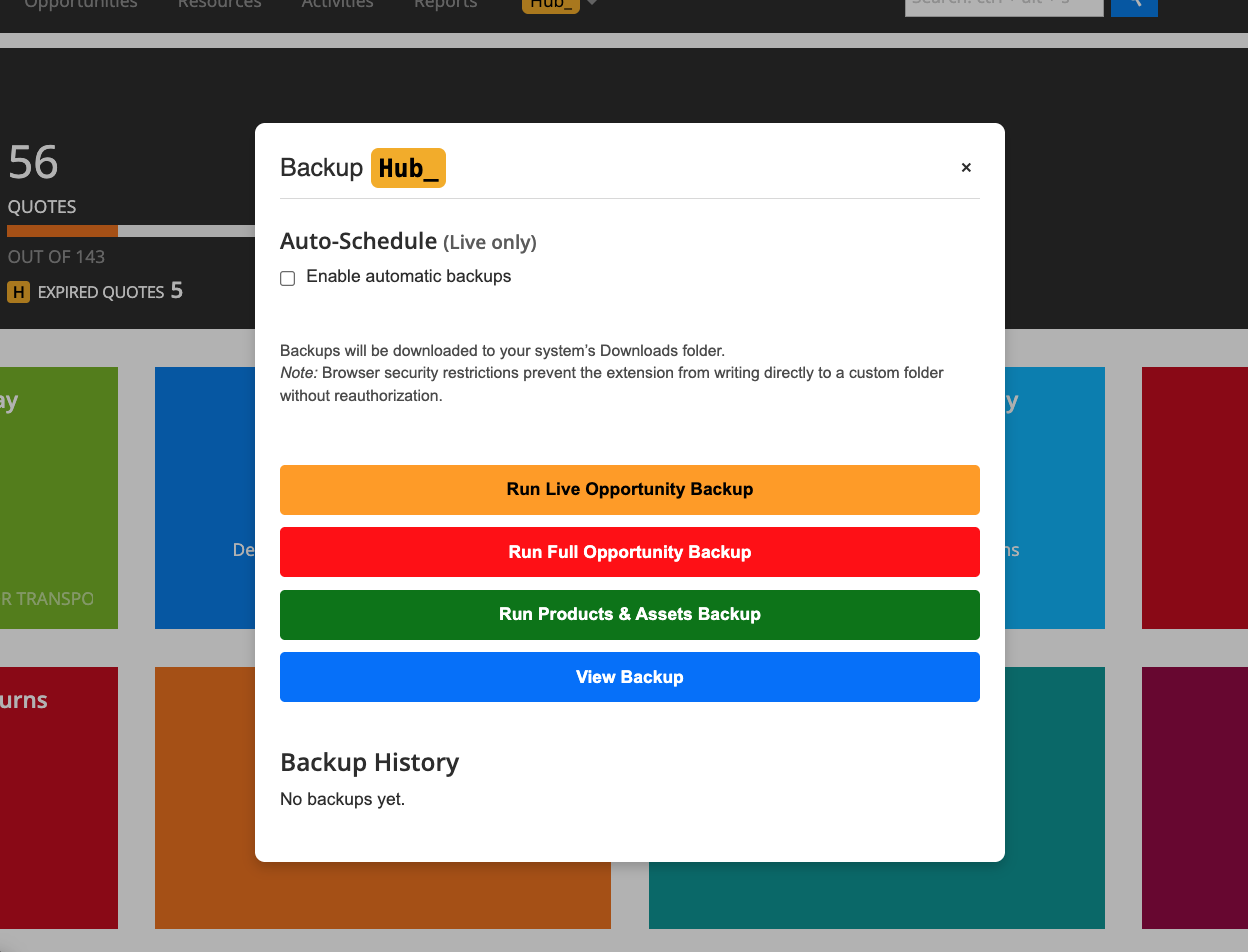

Backup Hub_

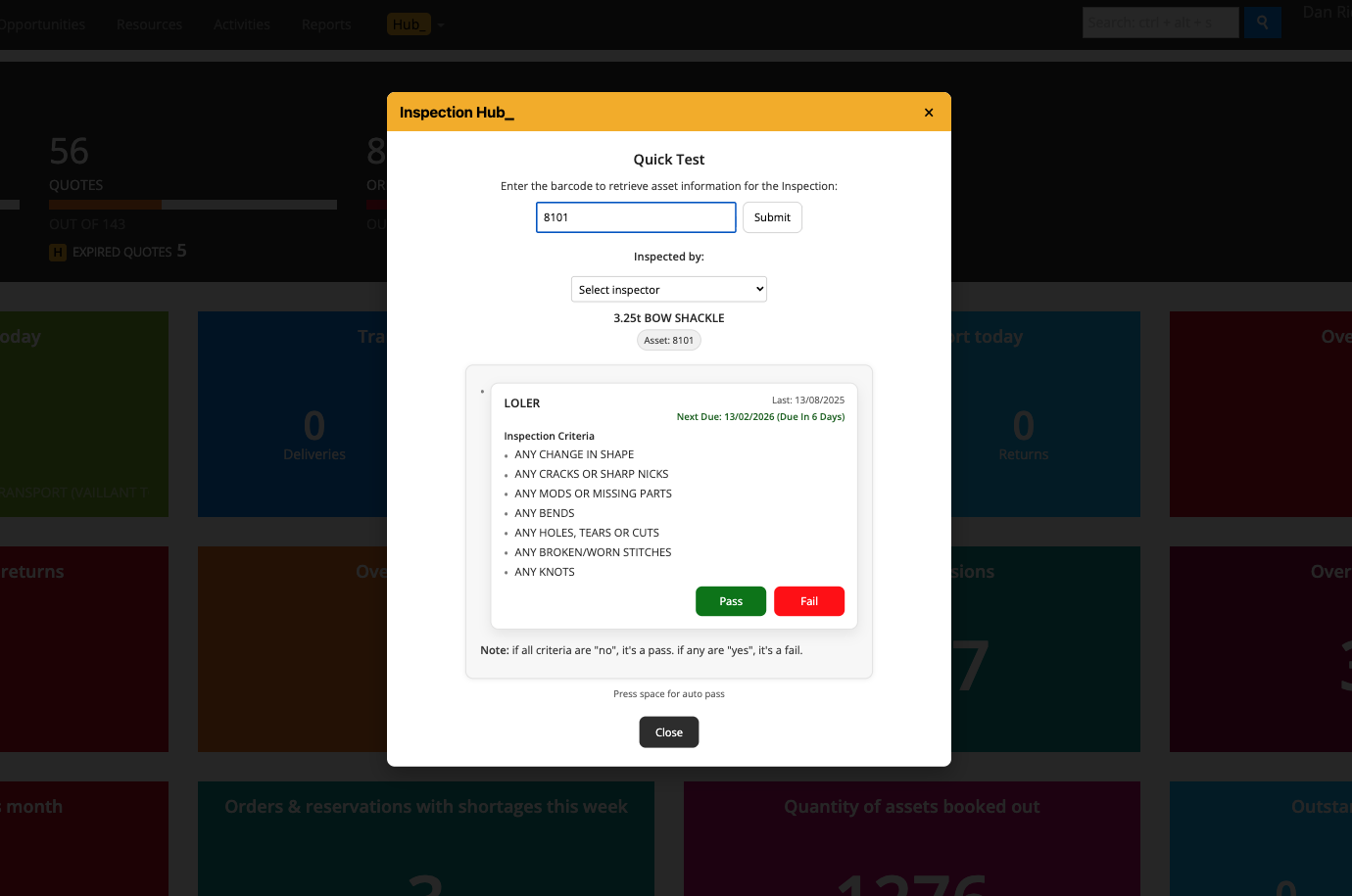

Inspection Hub_

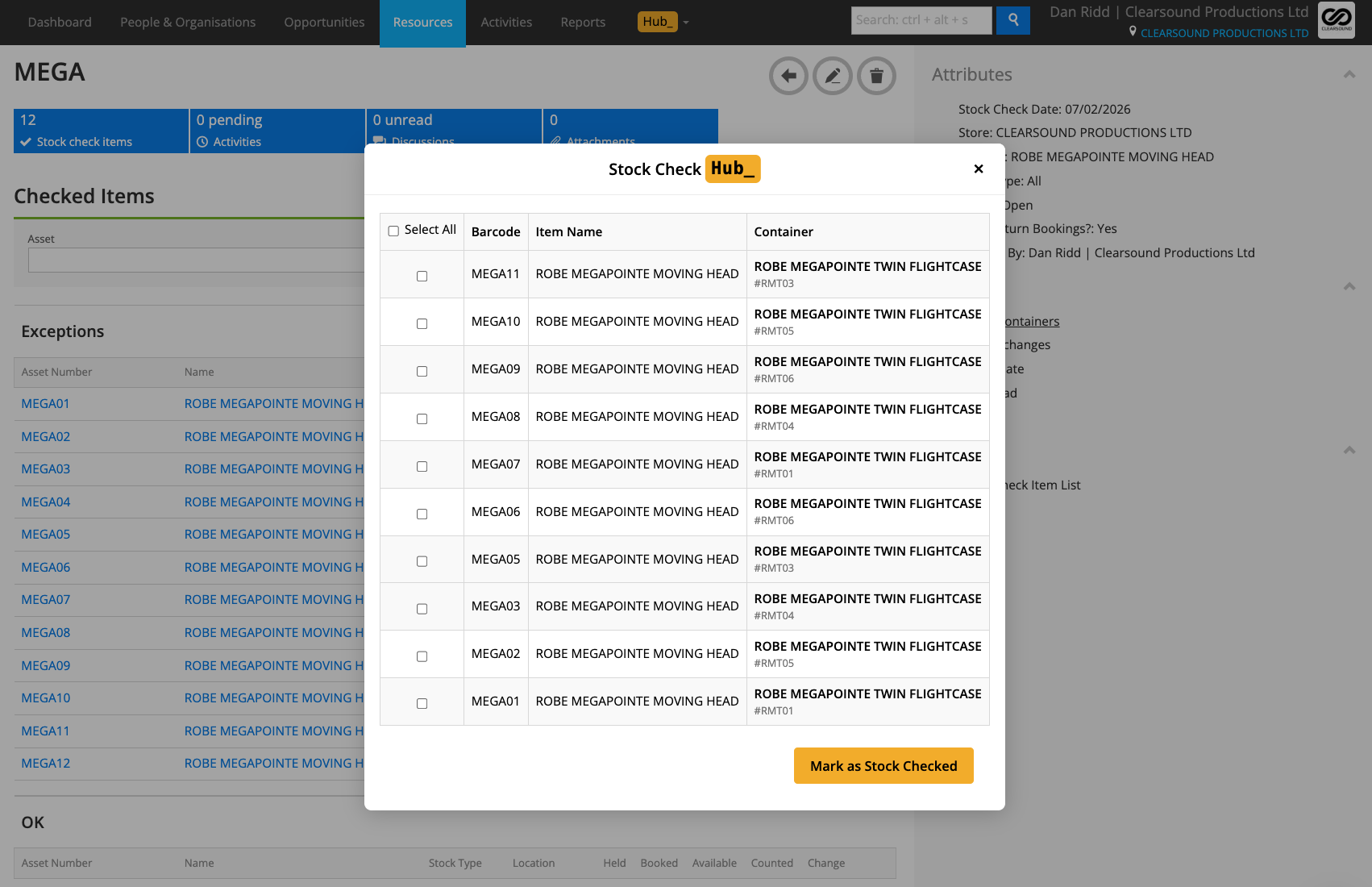

Stock Check Hub_

Clear-Up Hub_

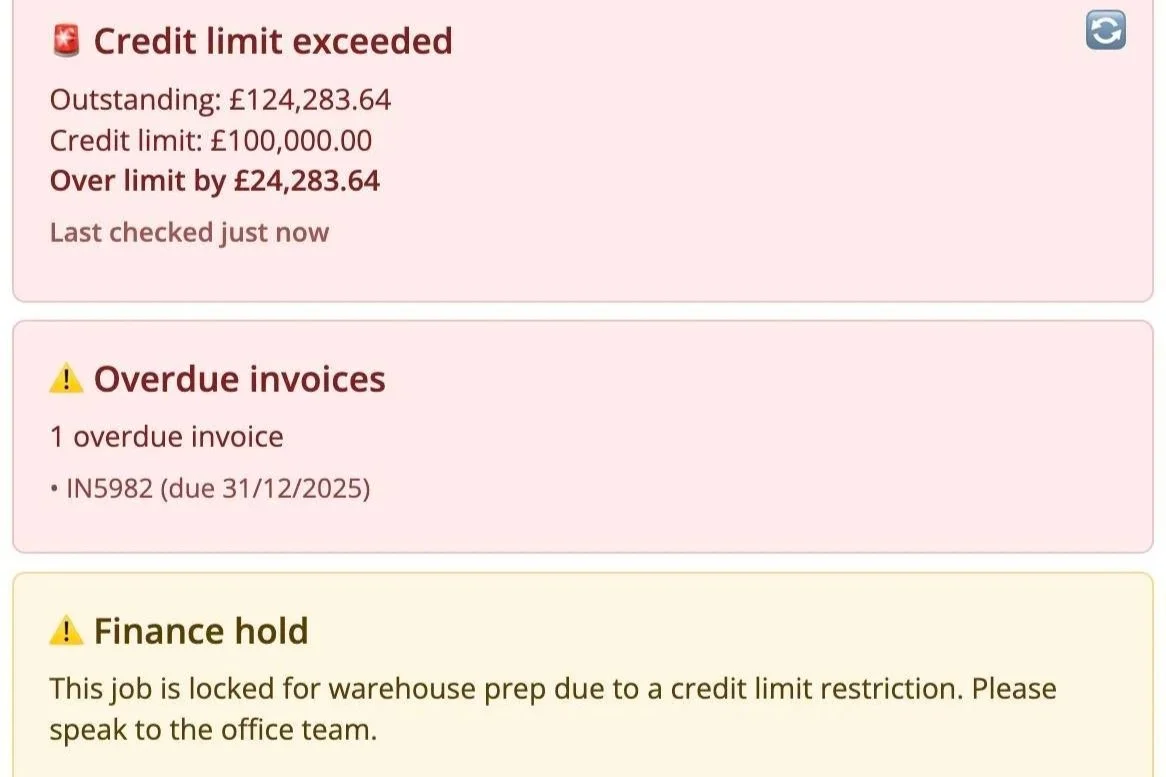

Credit Control Hub_

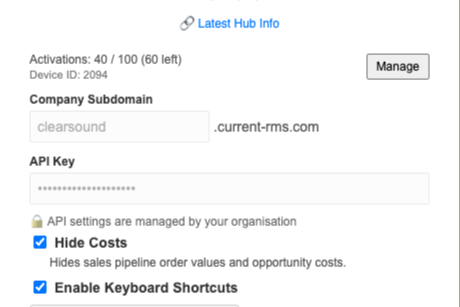

Settings Hub_

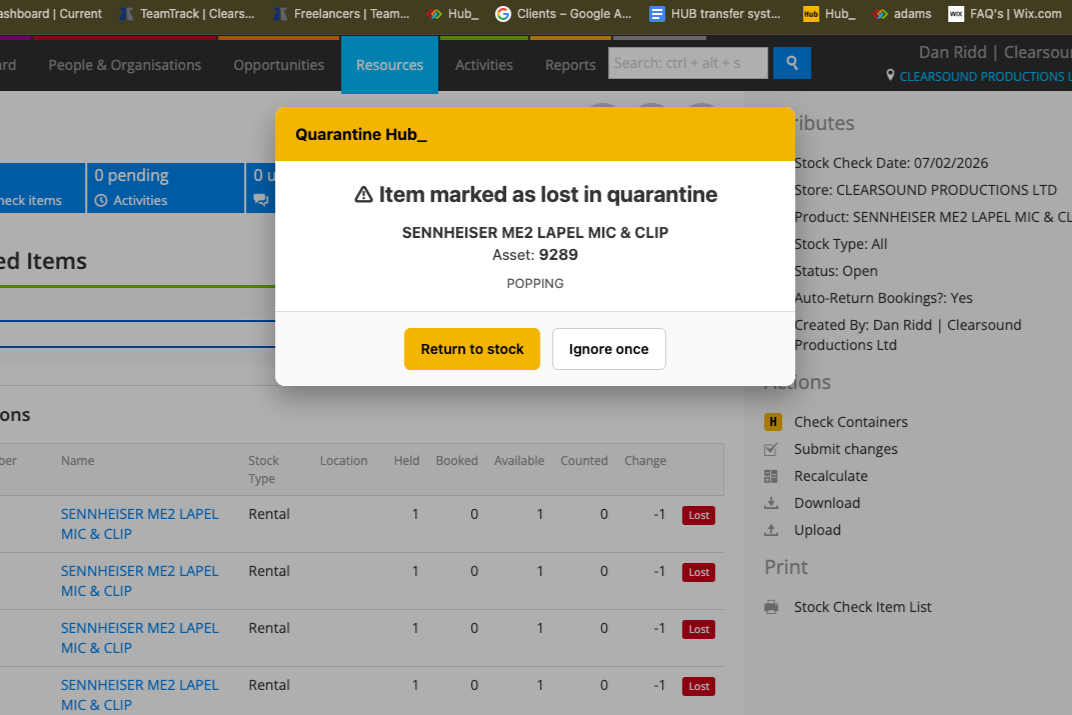

Quarantine Hub_

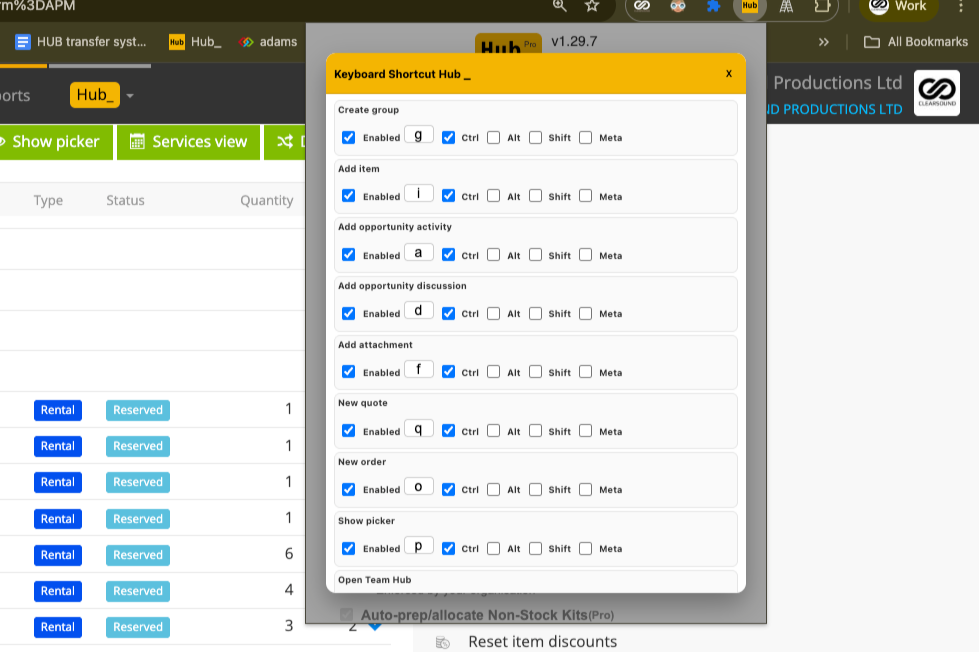

Keyboard Shortcut Hub_